What is different when we fly at 10 km altitude?

An aircraft is a highly complex structure consisting of several tens of thousands of individual components, some of which are even in double or triple amounts. There is a good reason for this, because an aircraft needs to stay in the air for short or long distances, and it needs to take off and land safely; but, it cannot stop at any time - as a car can - to have a quick look where a problem may be, if there is one. Moreover, first, one has to come down from a height of 10km to get on the ground - if there is such an opportunity.

At an altitude of 10,000 meters, almost everything is different. There is not enough air to breathe, it is also really cold (as low as minus 60°C) and the air pressure is so low a person would faint immediately. This is why the interior cabin is a so-called pressurized cabin; the air pressure is artificially generated and because there is almost none left on the outside, it is higher on the inside; also, the hull in which passengers and crew sit, must be reasonably stable in order to withstand the pressure difference. At the same time, its entire weight should be as light as possible. Sometimes a fully loaded aircraft (gross weight, kerosene, luggage and passengers) weighs between 50 to over 560 tons (Airbus A 380). Airplanes are a technical marvel.

By the way, it is the opposite on a submarine. The greater the depth, the heavier the pressure of the water masses from the outside. A submarine must therefore have a very thick (and at the same time heavy) hull.

How the air enters the aircraft cabin from outside

Due to theses different requirements, sometimes, here and there, technical compromises have to be made. One is, that the breathing air in the airplane is drawn through the turbines or engines ("bleed air").

Advantage number 1:

No additional compressor is needed to compress the 'little bit of air', to normal air.

Advantage Nr. 2:

By compressing the air for the combustion chamber, which then produces the necessary thrust, the heat increases in this compressor area to up to 450°C. Essentially, the (formerly ice-cold, thin) air drawn from there is already 'preheated' - a little.

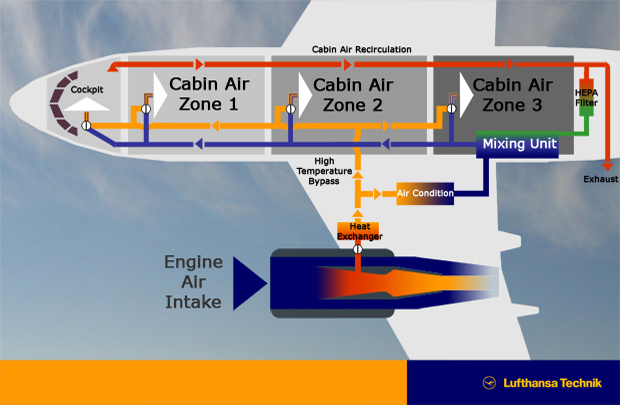

But: The bleed air is so hot that it has to be cooled down to about 200°C via a pre-cooler in order for it to be distributed through the various air conditioning elements in the aircraft, such as the cooling turbine (pack) and ventilation pipes (ducts). This is how it is described by Lufthansa: Breathing at 10,000 meters.

This is precisely where the potential problem of contaminated cabin air begins.

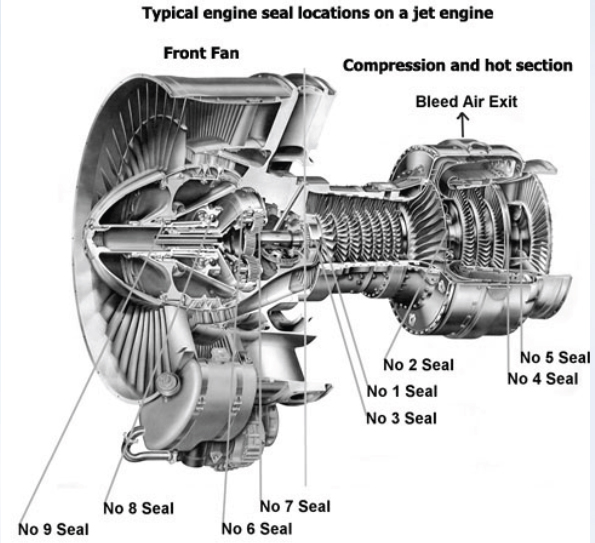

Several stages are involved to compress the air: The air is compressed by several turbines (blades) connected in series. All of them are connected with shafts (so-called turbine rotors), which (must) constantly rotate. This requires special bearings in special bearing housings. To prevent these bearings from running too tight, they are lubricated with special oils for engines. To prevent the oil from leaking, so-called labyrinth seals are often used , in short: there is no completely sealed seal. Rather, to prevent the escaping of oil from these bearing housings the engine has another (secondary) air circuit in the opposite direction. At least as long as everything is working perfectly.

This is described in detail (in English) by Prof. Dr.- Ing. Dieter SCHOLZ, lecturer at the University HAW in Hamburg who is responsible for the subjects: aircraft systems, aircraft design and flight mechanics. It can be found on his website: http://cabinair.profscholz.de, in on his list of lectures and presentations.: "Aircraft Cabin Air - Quality or Contamination?" (dated 20 November 2017).

Slide 9 shows the (toxic) substances that can enter the cabin via bleed air. It is a list from an EASA study:

- tributhyl phosphates (TBP)

- triphenyl phosphates (TPP)

- tricresyl phoasphate (TCP)

- trixylyl phosphates (TXP)

- amines

- volatile organic compounds (VOCs)

- organic acids

- aldehydes

- CO and CO2

- and above all: many other and especially so far unknown substances.

A colourful cocktail of chemical substances, so to speak. Toxic substances mostly.

The (only?) weak point in the safest means of transport

There are several seals in a turbine, some are made of carbon, which are considered to be particularly strong, but occasionally become brittle or tear. This is also a question of maintenance.

In the past, engines used to be overhauled every 3 to 4 years – after about every 15,000 flight hours. Specifically: the engines were dismantled from the aircraft and taken to overhaul operations, where they were disassembled into their individual parts. Every single part was carefully inspected, and if everything was in order, new bearing housing seals were always installed during the subsequent assembly. Just in case. This process generally ensured trouble-free operation with regard to the expected wear of these seals. Until the next overhaul was due.

These day things are different. The engine technology and the technology of checking the engine parts has been increasingly perfected and become more sophisticated, so the airlines have their engines checked less and less frequently. In 2009, for example, the engine manufacturer ‚General Electric’ congratulated the airline TUI-Fly that one of its "CFM 56" engines had already remained on the wing for 40,000 flight hours without ever having seen an engine workshop. The same in 2012, when the engine now had 50,000 flight hours on its back (respectively: wing). Meanwhile, one can generally say: the running times have tripled (a more detailed description of the procedure can be found here : Fume Events, Engines and Maintenance - compiled by an experienced pilot).

Technically speaking, that is fine - for the engines. However, the much faster wear of the seals is not taken into account. And if one (or even several) seals no longer work, Fume Events occur - in varying degrees and doses of toxic substances, which then enter the air conditioning system.

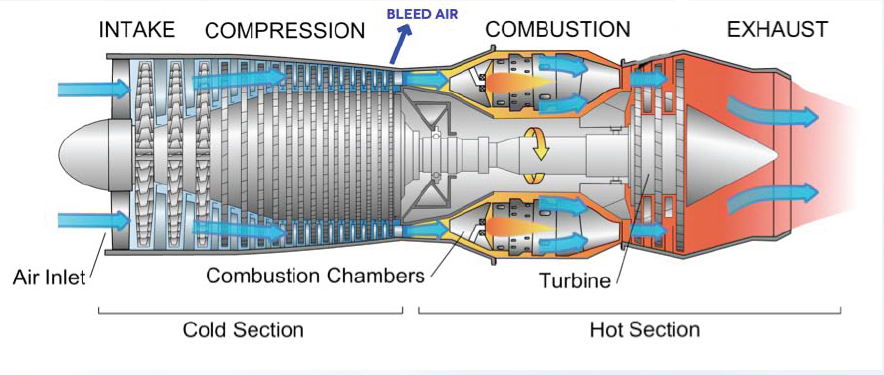

This is what the interior looks like in a model drawing. The division into "Cold Section" and "Hot Section" does not mean that within a few centimetres the temperature in front of the combustion chamber ("Combustion") rises from minus 50°C to plus 450°C in the combustion chamber - the bleed air, which is tapped before the combustion chamber, would have to be heated up separately. In fact, it is already so hot it has to be cooled down again.

The graphic is taken from a brochure of the Global Cabin Air Quality Executive (GCAQE): Contaminated Air Overview:

And this is what the bleed pipe looks like in reality. In a 2 1/2 minute video (by clicking on the picture) the British ex-pilot Tristan LORAINE, who like many others also became unfit to fly, explains how to drastically reduce the problem. This is done by installing a filter before the bleed air enters the aircraft interior.

So far, many, not all aircraft have so-called HEPA filters. But not at the air intake. These HEPA filters inside the aircraft recycle up to 50% of the used air in the cabin. In other words, some of the air inhaled by passengers is returned to the outside, while the other part is recycled through a filter of this type.

Before LORAINE explains the additional filter that should be installed, it shows a bleed air pipe:

In 2004, the British Civil Aviation Agency photographed what bleed air pipes look like when they are damaged by pollutants or dirt on the inside. The report can be downloaded at http://publicapps.caa.co.uk/docs/33/CAPAP2004_04.PDF. The two pictures can be found on page 46 (PDF count) and in chapter 2, page 14.

Figure 1 shows a new, 'unused' breathing-air pipe. Picture 2 an older one.

Perhaps breathing-air pipes should not look like a chimney pipe from the inside?

How the human organism reacts

Whether carbon or labyrinth seal(s) and regardless of how they work or leak:

Up at 10km height in the (still) air, the air pressure is regulated to an altitude of about 2,400m, i.e. 500m lower than the mountain ‚Zugspitze’ in the Bavarian Alps. This means that the air pressure is only 75% of what you are used to on the ground. As a result, the oxygen content is also significantly lower, to which human organisms react differently. You can read about it in the "Compendium of Aviation Medicine", on page "1-27". (not translated yet).

For example, foreign substances are metabolized differently. This means that the body tries to break down a substance which is not its own and which it does not recognise, or does not like very much, into other substances. At least those bodies that work.

This happens for each person in different ways - one faster, the other slower. With some substances this does not work at all, e.g. regarding deadly poisons, or other toxic substances.

In a completely different and compressed air environment as described above, medication can also react differently. Sometimes not at all. Or just at a fraction.

For passengers, a flight is a temporary thing. Flights longer than 13 hours (e.g. Frankfurt - Buenos Aires) are rare. As a rule, they are significantly shorter.

It's different for the crew. For them the cabin or cockpit is their workplace. The toxic body load is thus potentially higher. Significantly higher. And that's potentially where the problems for crews begin.

When a so-called leakage occurs and contaminated air flows into the cabin and/or cockpit, it is called a "Fume Event". This does not always have to be associated with smoke and/or bad smell (fumes). It depends on the substances that get into it: burnt oil or its additives (such as TCP), hydraulic fluids, de-icing agents in winter (which are designed for a temperature of 80°C) and much more. So far, about 200 such chemical substances have been identified. Not much is yet known about them, never mind about the interactions between them.

We analyze why this is the case in: Who, how, what and why. If you don't do research, you stay stupid. - Casuistic in occupational medicine (to be translated).

Other aspects

The health consequences for those affected are summarized under the term "aerotoxic syndrome". The effects can occur very suddenly, but they can also occur only in the medium to long term. We document all this and how employers and occupational medicine deal with it in: The Aerotoxic Syndrome in Occupational Medicine (not yet translated).

How the statutory accident insurance, specifically how the responsible professional association deals with this problem in general, is described in: The Berufsgenossenschaft Verkehr. Or: Who isn’t ill, doesn’t create cost (not yet translated). Employees are insured by the employers' liability insurance association in the event of accidents at work or work-related illnesses.

We will demonstrate what this looks like with one specific case: a pilot who has become unfit to fly, respectively is unable to work as a result of a Fume Event He is now fighting for to get it recognised as an occupational disease. His financial existence will also depend on it: Once a pilot - never again a pilot (not yet translated).

If you want to know more about the problem of contaminated cabin air and why it took so long before you even came across it, you can find more in our Chronology of Contaminated Cabin Air: a health problem becomes certainty.

All other texts displayed in the navigation bar on the right (smartphones: scroll down to the bottom!) concentrate on the question why the problem can no longer be ignored, but why nothing changes. This is where occupational medicine and statutory accident insurances come into play (more at www.ansTageslicht.de/Arbeitsmedizin - not translated yet).

Online am: 19.07.2018

Aktualisiert am: 19.07.2018

Inhalt:

- Fume Events Worldwide

- What is different when we fly at 10 km altitude?

- Contaminated cabin air: a health problem becomes certainty. The chronology of the socalled Aerotoxic Syndrome

- "Incidents": Incidents that do not usually appear in official statistics

- Lufthansa’s subsidiary ‚Germanwings’: December 19, 2010

- Health, Science and Economic interests in Aerotoxic Syndrome

- An UNCOVERING of Tricks, Methods and Strategies, how to downplay fume events

- 1 Reviewer - 2 Opinions: Prof. Dr. Stephan LETZEL

- Occupational Medicine in Germany: "Misleading Representation"?

- Tim van BEVEREN and the WDR documentary "Nervengift im Flugzeug" (Nerve Poison in Aircraft“): Chronicle of a film making, which turned into 2 (different) documentaries

- What Can You Do ?

Tags: